Expendable mold casting

Expendable casting uses sand, plastic, shell, plaster, and investment (lost-wax technique) moldings , clay or metal molds for the casting process. These molds are discarded after use. This method of mold casting involves the use of temporary, non-reusable molds.

Sand casting

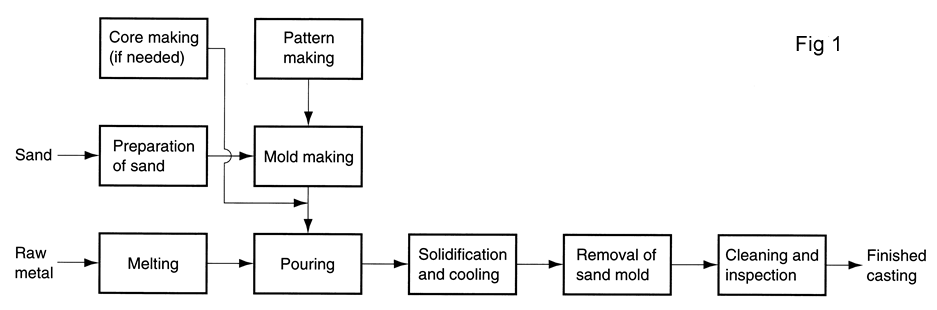

Sand casting is one of the most popular and simplest types of casting, and has been used for centuries. Sand casting allows for smaller batches than permanent mold casting and at a very reasonable cost. Not only does this method allow manufacturers to create products at a low cost, but there are other benefits to sand casting, such as very small-size operations. From castings that fit in the palm of your hand to train beds (one casting can create the entire bed for one rail car), it can all be done with sand casting. Sand casting also allows most metals to be cast depending on the type of sand used for the molds. Sand casting requires a lead time of days, or even weeks sometimes, for production at high output rates (1–20 pieces/hr-mold) and is unsurpassed for large-part production. Figure 1 shows Steps in the production in the sand casting

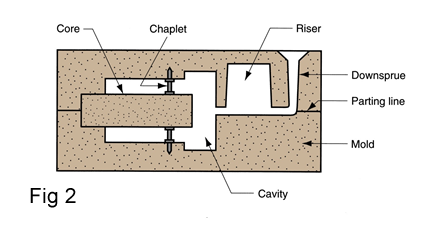

The following systems is used by Sand casting (fig 2):

Pattern

A designer or a skilled pattern maker builds a pattern of the object to be produced, using wood, metal, or a plastic such as expanded polystyrene. A full sized model of the part slightly enlarged to account for shrinkage and machining allowances in the casting. Pattern materials are such as: Wood - common material because it is easy to work, but it warps. Metal - more expensive to make, but lasts much longer Plastic - compromise between wood and metal.

Core

A core is a device used in casting and molding processes to produce internal cavities and reentrant angles. The core is normally a disposable item that is destroyed to get it out of the piece. It is inserted into the mold cavity for prior to pouring. The molten metal flows and solidifies between the mold cavity and the core to form the casting's external and internal surfaces. It may require supports to hold it in position in the mold cavity during pouring, called chaplets.

Making the Sand Mold

The cavity in the sand mold is formed by packing sand around a pattern, then separating the mold into two halves and removing the pattern .The mold must also contain gating and riser system If casting is to have internal surfaces, a core must be included in mold .A new sand mold must be made for each part produced(fig 2).

Plaster mold casting

Plaster casting is similar to sand molding except that plaster is substituted for sand. Plaster compound is actually composed of 70-80% gypsum and 20-30% strengthener and water. Generally, the form takes less than a week to prepare, after which a production rate of 1-10 units/hr-mold is achieved with items as massive as 45 kg and as small as 30 g with very high surface resolution and fine tolerances. The biggest disadvantage is that it can only be used with low melting point non-ferrous materials, such as aluminium, copper, magnesium, and zinc.

Shell molding

Shell molding is also similar to sand molding except that a mixture of sand and 3-6% resin holds the grains together. Set-up and production of shell mold patterns takes weeks, after which an output of 5-50 pieces/hr-mold is attainable. Aluminium and magnesium products average about 13.5 kg as a normal limit, but it is possible to cast items in the 45-90 kg range. Shell mold walling varies from 3-10 mm thick, depending on the forming time of the resin.

The sand used is finer than sand casting sand and is mixed with a resin so that it can be heated by the pattern and hardened into a shell around the pattern. Because of the resin and finer sand, it gives a much finer surface finish. The process is easily automated and more precise than sand casting. Common metals that are cast include cast iron, aluminium, magnesium, and copper alloys. This process is ideal for complex items that are small to medium-sized.